New Delhi: The automotive sector is credited with utilizing a substantial number of persons. But that does not necessarily mean that a business can be compelled to hire two times the number of persons it needs, claims Amit Kalyani, MD & CEO of the world’s 2nd-greatest forging business, Bharat Forge.

“Employment will be designed only if there are money investment decision and money deployment. You are not able to have firms overman, turn out to be inefficient and die in 5 years. The only way is to get firms to turn out to be more economical and grow and be an enabler,” he stated.

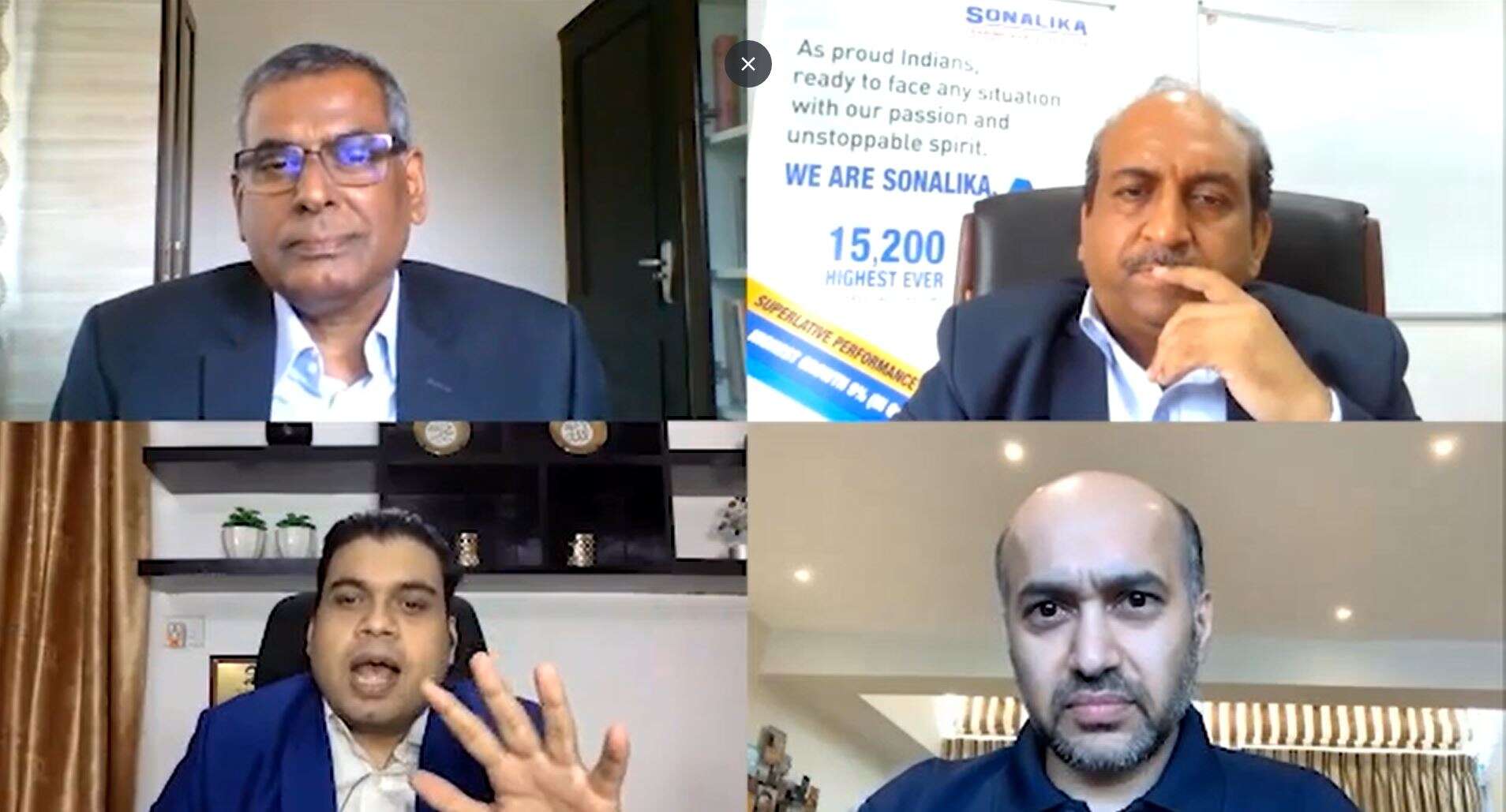

Kalyani was speaking at a panel dialogue hosted at ETAuto Sensible Manufacturing facility Virtual Summit 2020 where business magnates delved deep into the influence of business four. on the assembly line and workforce, the scenario for occupation development and labour legislation.

You are not able to have firms overman, turn out to be inefficient and die in 5 years.Amit Kalyani, Bharat Forge

In accordance to him, Key Minister Narendra Modi’s clarion call is a big phase in that path as it will increase localisation and open up up ample employment possibilities.

Is India capable plenty of to adopt industrial IoT

When it arrives to good production at automotive vegetation and deployment of business four., India is typically believed to be in a disadvantageous situation because of its huge dependence on international entities for technological innovation acquisition, skill gap and the scale.

However, Kalyani quashed the idea and asserted, “I really don’t feel there’s any downside of being Indian when it arrives to deployment of IoT alternatively it delivers overall flexibility, agility and skill to adapt to new conditions quite quick.”

“The Indian firms have not over-invested in the money and do not have also several preset assets which are a stress at these kinds of occasions, and that is where the full linked ecosystem arrives in. Compact, nimble firms below have a large vacuum that they can acquire up,” he stated.

India are not able to vie for the same stage of automation as in Japan or Europe. We want to see our geography and not just go by what’s occurring around the planet.Ashok Gupta, Sonalika Tractors

In the present-day problem, big international firms are in fantastic distress because of their preset prices which have designed a vacuum for compact, nimble firms in India to acquire up.However, Prabhakar Kadapa, MD and CEO, PSA Avtec, stated that the situation below is not of competency but of choosing the correct time to go forward and make the investment decision because adoption is subjective to the requirement and fiscal ability of a nation. As for India, the value of money is a lot larger than other components which set a problem mark on its skill to spend greatly.

Ashok Gupta, President-Functions at the world’s greatest tractor production business, Sonalika Tractors, has distinct suggestions. Sonalika, which has usually been manpower-intensive, has a meagre total of automation.

In accordance to Gupta, India are not able to vie for the same stage of automation as in Japan or Europe. A small stage of automation is surely needed on the store floors. Nonetheless, it has to be completed in tandem with Tier-one and Tier-2 players, then only can operational effectiveness be attained.

He added, “We want to see our geography and not just go by what’s occurring around the planet. In India, it is quite essential to spend, where we can have an precise worth from it. I would say this moment is not the correct time to make hefty investments as it will increase the value.”

The raging debates on upskilling, re-skilling and past but not the least manpower redundancy are not much behind when it arrives to automated assembly traces and good production.

As much as the positions in the automobile business are involved in terms of immediate manpower, there is not heading to be that a lot change even with good production and industrial IoT trending, opines Gupta.

The situation is not where India capable to adopt IIoT but choosing the correct time to go forward and make the investment decision the value of money is a lot larger than other components which set a problem mark on its skill to spend greatly.Prabhakar Kadapa, PSA Avtec

He stated, “Job reduction owing to automation can materialize in the warehouse phase, but as much as the generation vegetation are involved, immediate implementation of hefty automation in India is not heading to materialize.

Skilling the manpower is heading to be a considerable obstacle, feels Gupta incorporating that it is important to set up skill centres where the supervisor not only understands about the approach, but he also understands about the software.

At this time, 10% to 15% of factories in India is moving to a diversified degree of production four., according to the MD & CEO of PSA Avtec. All the vegetation set up in the past 3 to 4-years have some aspects of IoT. In the future 3 to 5 years, he expects most components of the four. implementation for operational effectiveness in the automotive sector.

However, Kalyani felt that the added benefits of business four. could only be reaped when 5G arrives and permits edge computing, edge analytics. Proper now, it is in infancy and does not have the richness of data and is not enhancing decision-creating.

Industrialising the hinterland

For a digital industrial revolution to course via Indian veins, the hinterland needs to be similarly industrialised, which could appreciably decrease production and transaction prices.

Kalyani stated, “Industrialising the hinterland can be a big accelerant as just one of the major troubles confronted by firms is get the white-collared administration and specialized gurus to go and are living in these regions.”

In the existing scenario, vegetation are importing labour into metropolitan areas which are ensuing in wastage of time and labour alternatively, the vegetation want to be set up in these regions to optimise value.

Bharat Forge MD proposed, “If we could build vegetation and have a immediate to an oblique ratio of one: 10, which means you have mainly immediate personnel with a quite lean oblique staff members making use of business four., the linked manufacturing facility to control the oblique aspect via a hub and spoke model.”

Echoing Kalyani’s perspective, Kadapa stated that the industries want to distribute all over the nation and not just be concentrated in metro metropolitan areas. Previously, the most considerable problem why vegetation had been not set up in remote regions is the availability of proficient labour and logistics problems. So there has to be a aim on generating an IoT ecosystem in the rural regions.

A different situation confronted by India at substantial, according to Kalyani is the full ‘federated model policy’ made by the central federal government.

The business four. transformation has to commence from the education process, which needs to get deregulated to make it more operate-oriented and aligned with what people’s skills are.Amit Kalyani, Bharat Forge

“They set Make in India, Ability India. All of these are fantastic guidelines, but the problem is we really don’t build vegetation in India. We build vegetation in Punjab, Maharashtra, Karnataka, Gujarat or Uttar Pradesh etcetera. States have to get aligned with what the centre is trying to do.”

There is a want for solitary-window guidelines, good infrastructure, good quality of everyday living for persons doing the job in these regions, instruction and skilling centres for generating production possibilities to tap the international firms moving out from a specific geographic spot.

Overhauling the education process

Kadappa stated the full transition to business four. is heading to have an influence not only on the business but on the university’s curriculum which needs to contain Artificial Intelligence, IoT deployment etcetera.

He added, “Some stage of change is heading on, but it has to go into a lot further understanding to make them sufficient and capable to be utilized.”

The business four. transformation has to commence from the education process, which needs to get deregulated to make it more operate-oriented and aligned to what people’s skills are, voiced Amit Kalyani.

He proposed, “I feel right after 12th conventional, you can have just one or two-12 months program, which is like a boot camp, which teaches you the type of digital technological innovation capabilities, Math and Science fundamentals plenty of for you to get into a place of work and then maybe the business alone will pay for you to go to a faculty of your curiosity.”

Also Read through: ETAutoSmartFactory: How digital production prepares automakers for new typical

More Stories

Event Coverage: ImportExpo Toronto 2022

2023 Nissan Versa starts at $16,825

5 Things to Do After a Catastrophic Car Crash