New Delhi: For the Indian vehicle market, coronavirus is a *enterprise functionality nightmare*. Now close to a few months into the true disaster that has just about paralysed China, there is however no indicator of the affect easing whenever quickly.

The subsequent two months (March and April) will definitely witness stagnation in car creation if the factory closure in China continues until February conclude.Ashim Sharma, Lover & Team Head, Nomura Study Institute

The 10 per cent creation lower introduced by automakers like Hero MotoCorp and TVS Motors for the month of February and Mahindra’s struggle to finish the final batch of its BS-IV cars are very clear indications that Indian authentic tools makers (OEMs) can’t continue to keep their crops functioning without having the aid of Chinese elements. Market watchers say the situation will even more intensify as the firms have exhausted their further elements stock constructed up for the Lunar New Yr holidays beginning early February.

“The subsequent two months (March and April) will definitely witness stagnation in car creation if the factory closure in China continues until February conclude,” Ashim Sharma, Lover & Team Head, Nomura Study Institute said underlining that it is practically extremely hard to discover a alternative of all the Chinese elements. “Wuhan is the production hub of some of the important components of the vehicle market. Sourcing these kinds of elements from other areas will come with further cost stress,” Sharma additional.

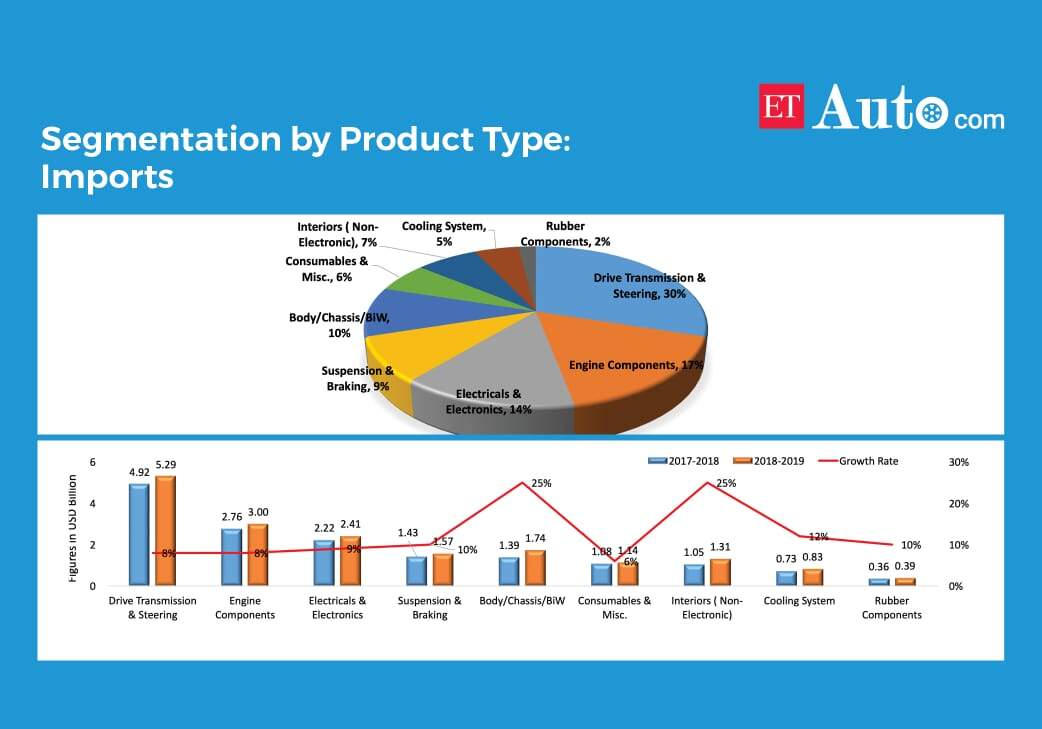

Source: ACMA, ETAuto Study

For perspective, major casting elements and electronics components sourced from China are upto twenty five per cent less costly than their Korean counterparts as per professionals. The components at threat assortment from higher tech electronic chips and sensors down to nuts and screws. The Automotive Component Manufacturers Affiliation (ACMA), the apex overall body of the Indian vehicle part market said it is carefully checking the situation but it can be as well early to say what the affect on OEMs offer chain will be.

“It is however a wait around and watch situation for us as the firms in China had been intended to open on the 10th of February but they are nonetheless to resume functions. We are however hoping to gauge the situation,” said Vinnie Mehta, Director-Basic, ACMA. On the other hand, he underlined that some important components are manufactured only in China and the unavailability of these kinds of elements could possibly disrupt the overall offer chain of the OEMs.

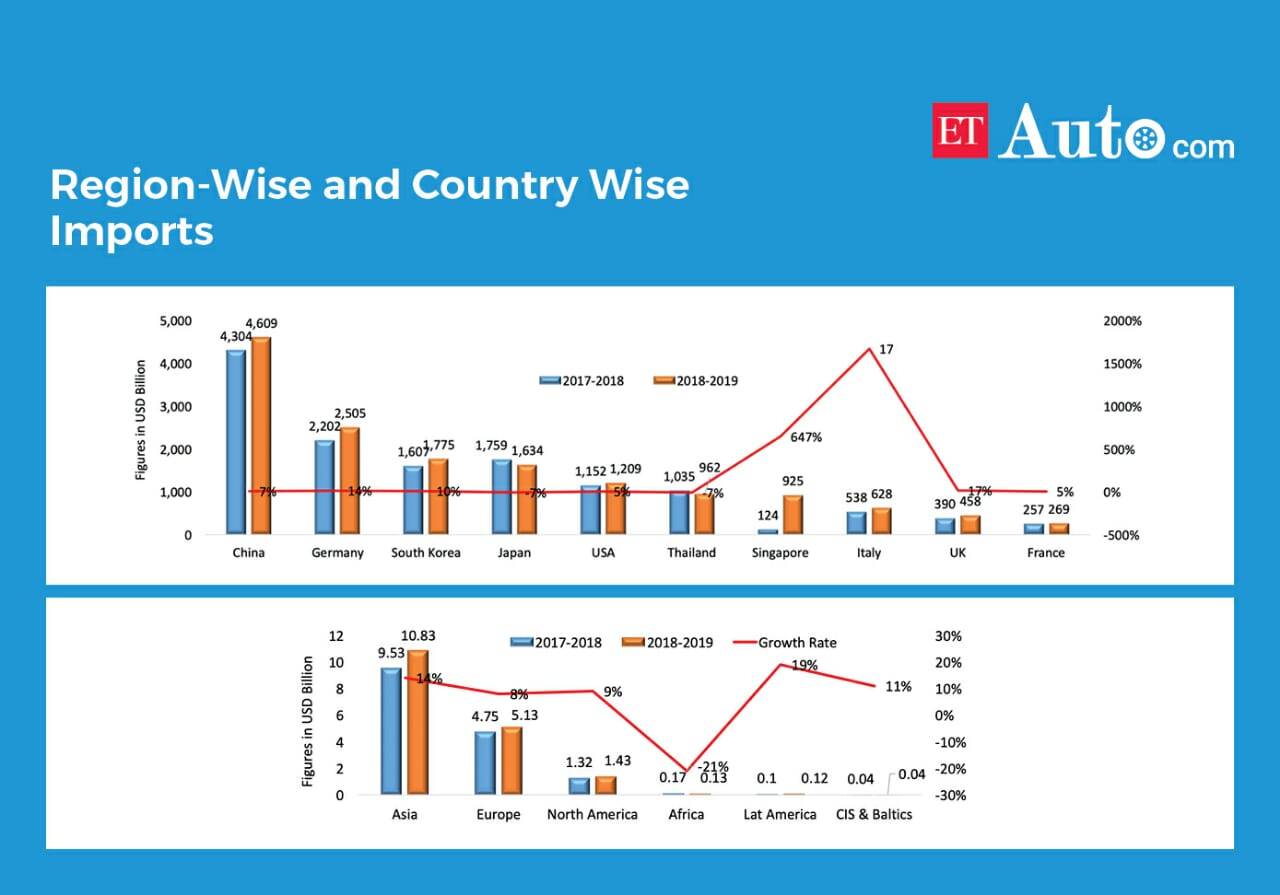

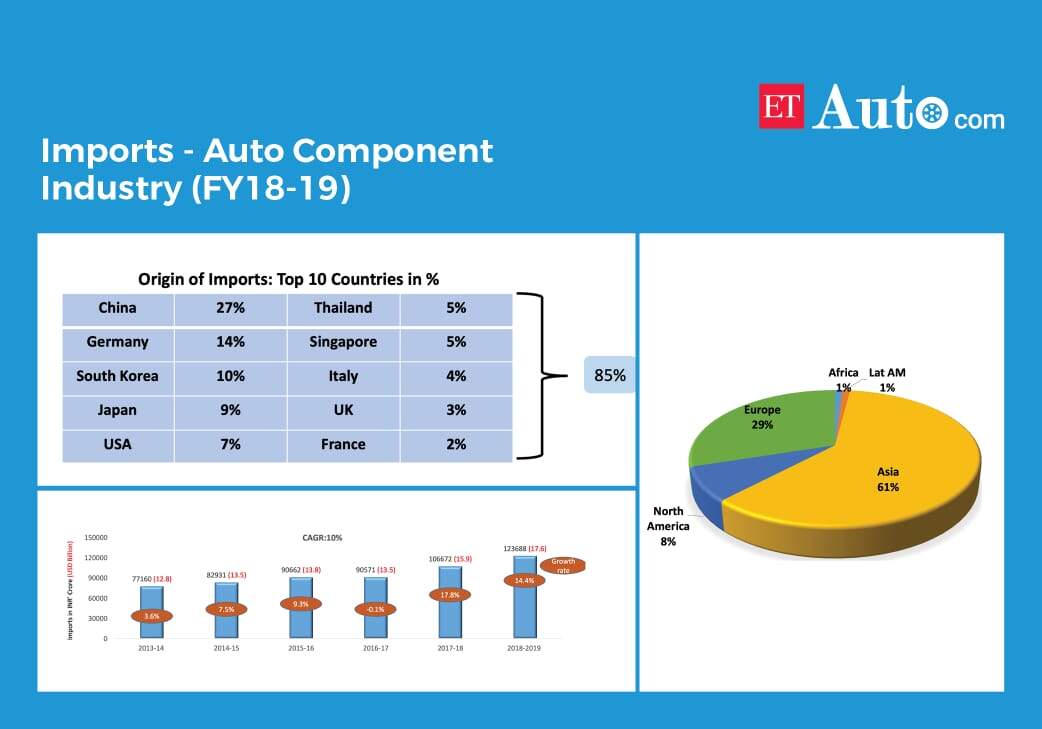

China is a critical provider of elements to vehicle crops around the globe — delivery just about $35 billion of elements in 2018, as per UN facts. In the financial calendar year 2018-2019, India imported components worth $4.six billion from China which accounted for 27 per cent of the overall imports into the state. In the to start with half of the present-day fiscal, India’s imports from China stood at $two billion.

Source: ACMA, ETAuto Study

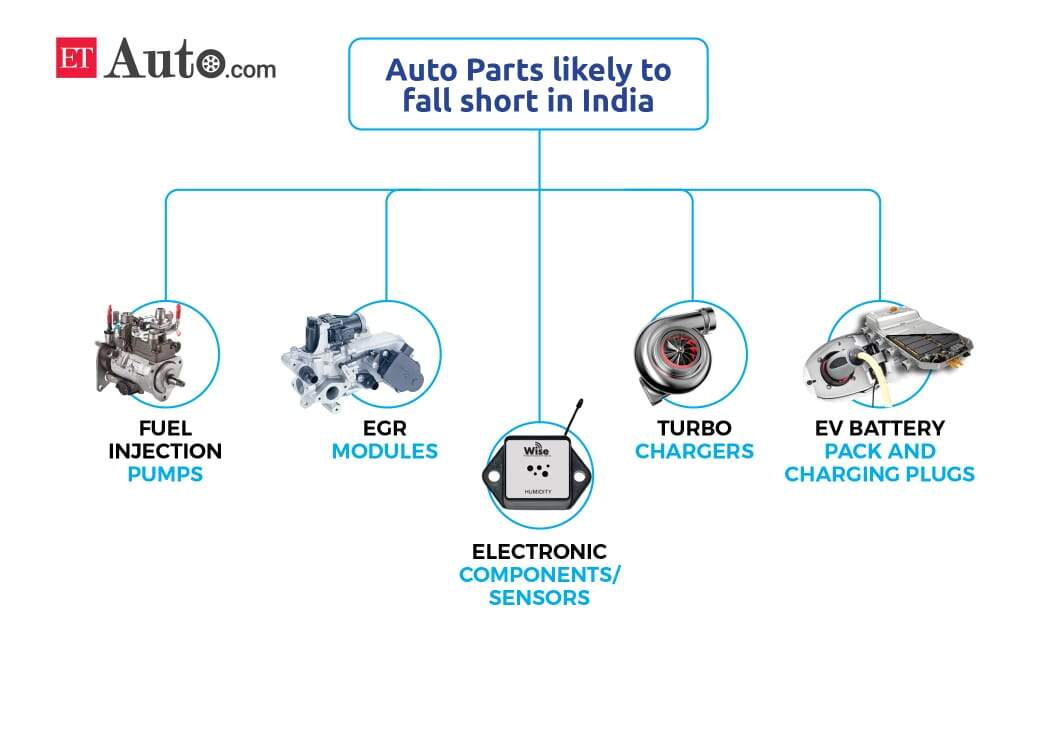

According to ICRA, South-East Asia countries enjoy a important role in the automotive offer chain and domestic OEMs source important components and sub-components which include gasoline injection pumps, EGR modules, electronic components, turbo chargers and so forth. from these marketplaces, which in flip right or indirectly rely on China.

Now, the market is broadly struggling with challenges on two fronts – to start with is to judiciously manage the offer-chain and next is to management the car selling price hike. According to Puneet Gupta, associate director, automotive forecasting, IHS Markit, the a few-fold enhance in sea-freight charges due to coronavirus disaster could pressure vehicle firms to enhance car charges.

“The sea freight charges have shot up from $five hundred per container to $1500 per container. With a few occasions enhance in freight charges, there are acute likelihood that automobile makers may hike car charges due to increasing delivery cost,” Gupta described.

Source: ACMA, ETAuto Study

The outlook for the to start with half of 2020 already seemed challenging, but that now appears even worse than anticipated. Ravi Bhatia, president of automotive enterprise intelligence provider Jato Dynamics highlighted that situation issuance of “force majeure” certification by Chinese federal government and trade bodies to part makers and OEMs could possibly extend the creation halts until mid of this calendar year.

“Chinese government’s provision to invoke pressure majeure in buy to suspend contracts is leaving several Indian OEMs in full lurch. At a time when the full production approach is in doldrums, finding a next choice will be a challenging task for several firms,” Bhatia observed.

Source: ACMA, ETAuto Study

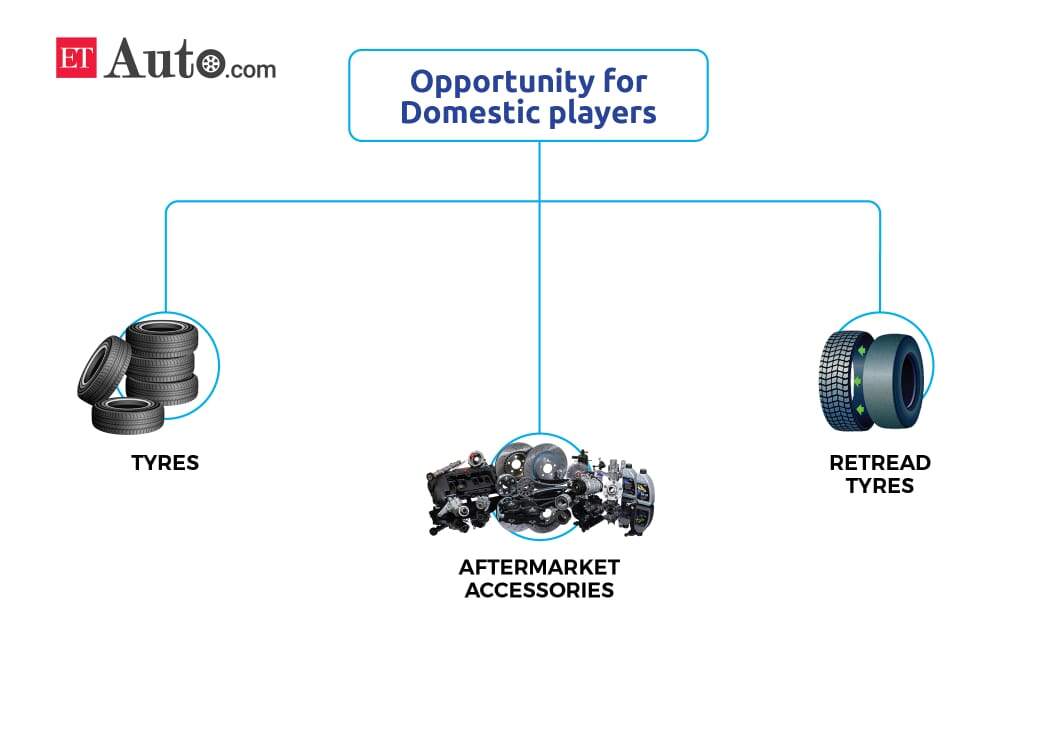

Many analysts however opined that there is a great option for multinational suppliers to manufacture elements in India for the domestic market and export marketplaces. Foremost business car maker, Ashok Leyland, said there is no direct affect on creation due to coronavirus. The Chennai-based mostly organization is, however, cautious about the situation and clearly checking it.

Tyre production firms, on the other hand, are reasonably immune to the novel virus outbreak due to their lesser dependence on the Chinese market. In 2018-19, $430 million new tyres had been imported, out of the $127 million was from Thailand and $ninety two million was imported from China. Furthermore, $seven million worth of retired tyres components had been imported from Thailand.

Coronavirus was to start with detected on December 8, 2019. By the conclude of January, about nine,700 instances had been detected and 213 fatalities claimed. By February 3, there had been seventeen,000 confirmed instances and, at the time of publication, the instances of the novel coronavirus has risen to about 70,000 around the globe.

The most up-to-date reviews of new coronavirus pressure emerging in Korea could irritate the complications. South Korean carmakers Hyundai and Kia Motor would be the to start with impacted by any closures as they have big portions of electronics primarily coming from their home marketplaces. “We are assessing the situation. There is no worry nonetheless, but if it continues then we need to push in all different means of sourcing for hasslefree functions,” said a senior executive from an automotive important.

Source: ACMA, ETAuto Study

Other than IC engine cars, the electric car gamers will also feel the warmth of coronavirus outbreak due to the lag in the procurement of components and batteries from China. “When components can be taken treatment of to some extent at-minimum in the short run as makers ordinarily continue to keep two to 3 months’ shares batteries and battery cells on the other hand, are imported in little batches and given that they come with a confined warranty – makers do not maintain big inventories,” said Sohinder Gill, director common, Modern society of Manufacturers of Electric powered Autos (SMEV).

In January, Fitch Solutions projected car creation in India to agreement by 8.3 per cent in 2020 as the vehicle market faces increasing threat of offer lack due to China’s coronavirus outbreak, potentially hitting domestic output if the virus spreads in the state. Analysts also reckon that even if factories reopen in China by the conclude of this month, it’s unclear if they will be capable to run as usual in the in close proximity to expression as their to start with and foremost obstacle would be lack of workforce.

More Stories

4 Simple Hacks to Pick a Good Car Repair Shop in Houston

Jeep Avenger Review (2022) | Autocar

Flat Rat: A Slammed1950 Ford COE Firetruck On Air